Detail

The Lubricator is a device which ejects drops of oil into the flowing compressed air to automatically

provide proper internal lubrication for an air-operated tool or other devices. Oil is injected only when

there is a flow of air through the lubricator. The drip rate is regulated using an adjusting screw. For

general use, 6 drops per 1000 liters of air are sufficient. This is a mist-type lubricator. The proportion-

maintaining lubricator supplies proportionate oil to the compressed air in a precisely metered quantity.

A regulator ensures that the amount of oil mist is proportional to the flow rate. The pressure drop that

occurs when the air flows through a venturi nozzle is used to convey oil from a reservoir to the drip cap

(sight feed dome). From here, the oil drips through a syphon tube into an air passage. As the oil leaves

the syphon tube, it is atomised by the flowing air. Oil can be filled during operation.

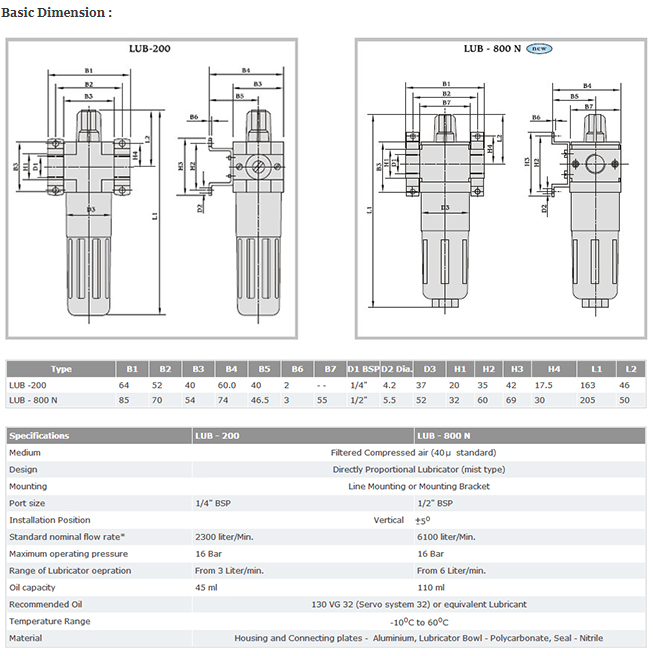

Dimentions: